Moisture Holders

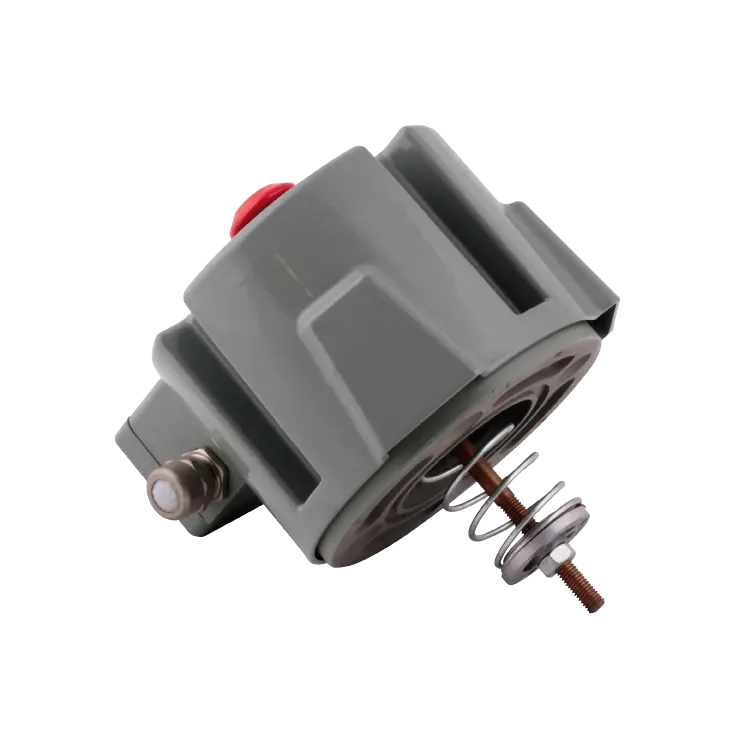

Moisture Holders 0,5kg – 1kg Form A, B, C (DIN 42567)

The top and the bottom sections are casted aluminum and electrostatic powder painted. The shafts are made of nickel plated steel and the sieves are made of zinc sheet. Container cylinder is glass or polycarbonate depending on the customers’ request. Oil bowl is of polycarbonate and the bowl holder is made of CrNi material.

Do you have questions about our product, would you like personal advice, or do you want to place an order? Our team is happy to assist you with help and guidance!

Operation principle

When the transformer gets air in, an air flow from and to the oil bowl occurs. The oil layer in the bowl prevents the dryer material from continuous contact with the damp external air and cleans the air flowing in. If the operation temperature of the transformer decreases, the volume of the isolation oil gets smaller. During this lessening, an amount of air equal to the lessening amount is absorbed into the oil bowl through air holes. This air then transfers to the expansion vessel and contacts with the oil layer. During this transfer, air contacts with the dryer material and leaves its moisture there. With the heating of the oil in the transformer tank, the air inside flows out from the opposite direction of the moisture holder.

Capacities

In the selection of the size of the moisture holders, various factors such as oil volume in the transformer, required life of the silica gel charge, operating cycle of the transformer, temperature and moisture content of the ambient air should be taken into consideration by the transformer designer.

Suitable for this

Quality and expertise from a single source

For over 60 years, we have been successfully operating in the market as an owner-managed company. We combine tradition with innovation and stand for fairness and the highest quality. Founded more than six decades ago, we have continuously developed and established a recognized name.

Learn more about the company